Laser Cutting

CO2 laser cutting allows nimble solutions to changing requests and demands.

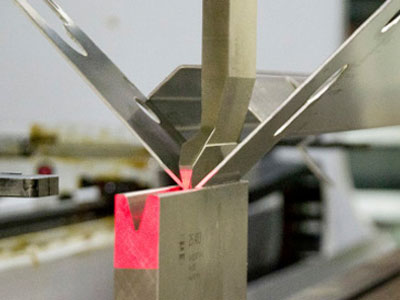

Laser cutting is the technology that splits steel by heating it to melting temperature. This is achieved through two simultaneous processes: stimulated emission of radiation and a CO2 jet at very high pressure. The section of material thermally affected by the radiation is very limited, which avoids distortions of the material and changes in its physical properties

Lasers are a fast, clean and precise multifunctional tool which allows the machining of a wide range of materials by cutting both simple and complex pieces. With them we can also offer nimble solutions to changing requests and demands.

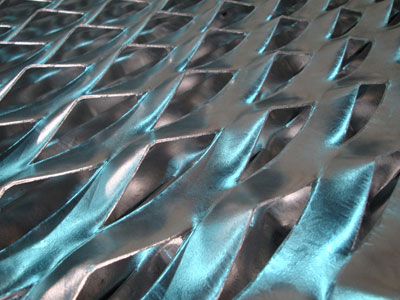

A perfect, fast and flawless cut.

Guaranteed repeatability in the different manufacturing runs.

Laser power can be adjusted automatically during machining so that angles and small edges are cut with the greatest precision

The precision of the cut and the lack of mechanical contact with the workpiece significantly reduce distortions and impurities. Burrs no longer exist and subsequent cleaning work is avoided.

Material utilization due to minimal evacuation of the material.

Tube and section cutting

In addition to the precision of the technology, there is the precision of a nimble service adjusted to the characteristics of each workpiece and task.

Great versatility in the definition of the edge to be cut. We can define any shape and complexity in the final cut with great precision in the details.

There is no need for cutting dies and it is particularly suitable for pre-cutting and trimming excess material, developing more complex edges on the workpieces

The cutting walls are parallel to each other, perpendicular to the workpiece and not rounded as in other cutting techniques.

Wide range of materials and thicknesses.

The drive is robotized to maintain a constant distance between the electrodes and the outer surface of the workpiece.

About the Process

We own 2 laser cutting Prima Power PLATINO® machines size 1530 with laser powers of 3 kW and 4 kW, with which to quickly and precisely cut a wide range of materials and thicknesses with no need of manual adjustments. Thanks to their automation solutions, they are ideal for both small runs and large-scale production.

- CO2 laser generators of 3 kW and 4 kW by Prima Electro: wide range of thicknesses from 0.5 to 25 mm and the highest CO2 laser efficiency.

- Rotary axis (lathe) for tube and section machining.

- Great productivity, better performance while running

Contact Us

(+34) 93 868 00 80

TruLaser TRUMPF 5030

✓ Outstanding quality

With TruFLow CO2 laser you will obtain optimum cutting results free of burrs.

✓ Optimal edges

Thanks to BrightLine you will obtain smooth cutting edges in stainless steel.

✓ Intricate cutting even in thick mild steel

With the CoolLine function, you can even create fine edges in thick mild steel with outstanding quality.

✓ Perfect nozzle quality

Smart nozzle automation ensures a high quality of nozzle – even in fully automatic operation.

|

Dimensions Length Width Height |

9950 mm 4600 mm 2400 mm |

|

Maximum Speed Simultaneous |

300 m/min |

|

Working Range X Axis Y Axis Maximum Workpiece Weight |

3000 mm 1500 mm 1800 kg |

TruLaser TRUMPF 3040

✓ Outstanding quality

With TruFLow CO2 laser you will obtain optimum cutting results free of burrs.

✓ Optimal edges

Thanks to BrightLine you will obtain smooth cutting edges in stainless steel.

✓ Flexible Layout

You can adapt the installation completely to your requirements – transverse layout is even possible.

✓ Processing tubes

Cut tubes directly on your flatbed laser machine with RotoLas.

✓ Intricate cutting even in thick mild steel

With the CoolLine function, you can even create fine edges in thick mild steel with outstanding quality.

|

Dimensions Length Width Height |

– mm – mm – mm |

|

Maximum Speed Simultaneous |

– m/min |

|

Working Range X Axis Y Axis Maximum Workpiece Weight |

– mm – mm – kg |

Related Services

CNC Bending

Metal sheet bending into a wide range of shapes assisted with 3D numerical control tools.

Welding

Over 60 years of experience with steel welding, smelting, etc.

Assembly and Finish

We can provide finished ready-to-assemble products.

Contact Us

C/ Thomas Edison, 17-18 | 08280 Calaf (Barcelona)

Spain +34 93 868 00 80

info@insda.com